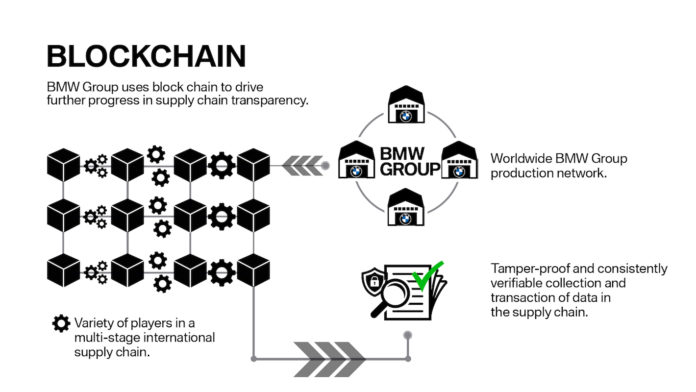

The BMW Group is using blockchain in purchasing to ensure the traceability of components and raw materials in multi-stage international supply chains.

“In 2019, we conducted a successful pilot project for purchasing front lights. This year, we want to expand the project to a large number of other suppliers,” said Andreas Wendt, member of the Board of Management of BMW, who is responsible for purchasing and supplier network.

For the BMW Group’s purchasing experts and its suppliers, ensuring transparency therefore involved considerable manual effort. The BMW Group initiated the PartChain project to ensure seamless traceability of components more or less “at the push of a button” and provide immediate data transparency in complex supply chains for all partners involved going forward.

“PartChain enables tamper-proof and consistently verifiable collection and transaction of data in our supply chain,” said Wendt.

In the long term, the BMW Group also expects the project to enable complete traceability of critical raw materials, all the way from mine to smelter.

“This move is designed to take the digitalisation of purchasing at the BMW Group to the next level,” said Wendt. “Our vision is to create an open platform that will allow data within supply chains to be exchanged and shared safely and anonymised across the industry.”

PartChain uses cloud technologies like Amazon Web Services and Microsoft Azure in addition to blockchain solutions. This allows the origin of components to be tracked between all participating partners without any risk of manipulation.

The 2019 pilot project already involved two of the BMW Group’s total 31 plants as well as three locations of the supplier Automotive Lighting. This year, the platform will be rolled out to about ten suppliers.