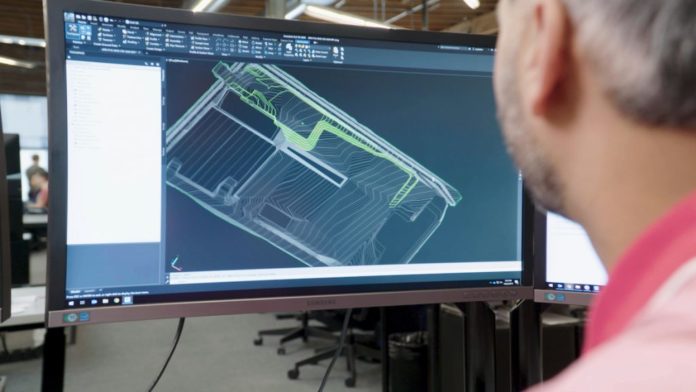

Autodesk and Virgin Hyperloop One have forged an alliance to explore new opportunities in extending the value of Building Information Modeling (BIM) for transportation route optimisation and improved digital engineering and construction workflows.

“Virgin Hyperloop One is pushing the boundaries of transportation efficiency,” said Josh Giegel, CTO of Virgin Hyperloop One.

“Together, (we) will explore ways to optimise hyperloop routing and operations – in a way that not only propels the hyperloop industry forward, but also has ancillary benefits to more traditional forms of transportation such as railway and highway route optimisation,” Giegel said.

Virgin Hyperloop One’s technology features depressurised tubes that carry on-demand passenger or cargo pods at speeds of up to 670 miles per hour, powered by magnetic-levitation and electric propulsion.

The depressurised tube infrastructure eliminates the impacts of air-drag and friction, requiring less energy and cost to operate, and allows travel to occur at “exceptionally” high speeds.

“Autodesk technology is in the DNA of much of the built world everywhere – and I mean everywhere,” said Nicolas Mangon, VP of AEC Business Strategy at Autodesk. “With the global population expected to hit 10 billion by 2050, the way infrastructure is designed and constructed, and how we move people and goods, must change.”

Autodesk technology has been used on some of the most complex building and infrastructure projects on the planet, including Pan Borneo Highway Sarawak, New York Metropolitan Transit Authority’s East Side Access, the San Francisco Airport Terminal 1 redevelopment, Dubai’s Museum of the Future, and the world’s tallest skyscrapers including the Shanghai Tower.

By bringing in the context of the real world into the design and engineering phases of a project, Autodesk and Virgin Hyperloop One hope to more efficiently calculate costs across the entire lifespan of a project – design, construction, operations, and maintenance.